High Density Pvc Foam Sheet

- PREMIUM

- Jinan City, Shandong Province

- 3-5days

- 2000tons per ton

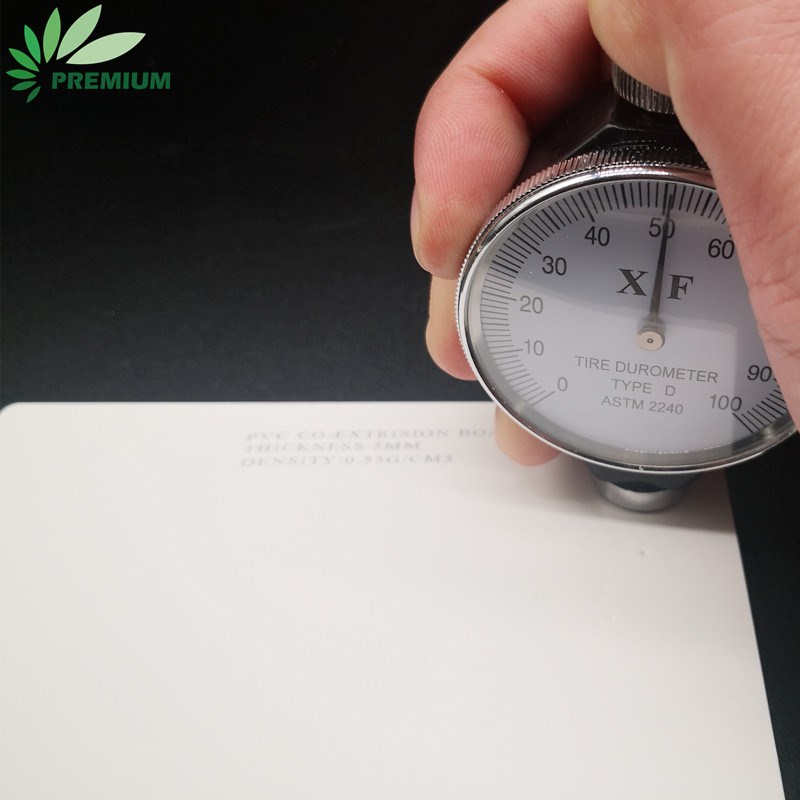

1. High Density Pvc Foam Sheet, density max can be 0.9g/cm3=900kg/m3

2. Surface hardness: 90D

3. Good nail hodling capacity

4. Anti scratch

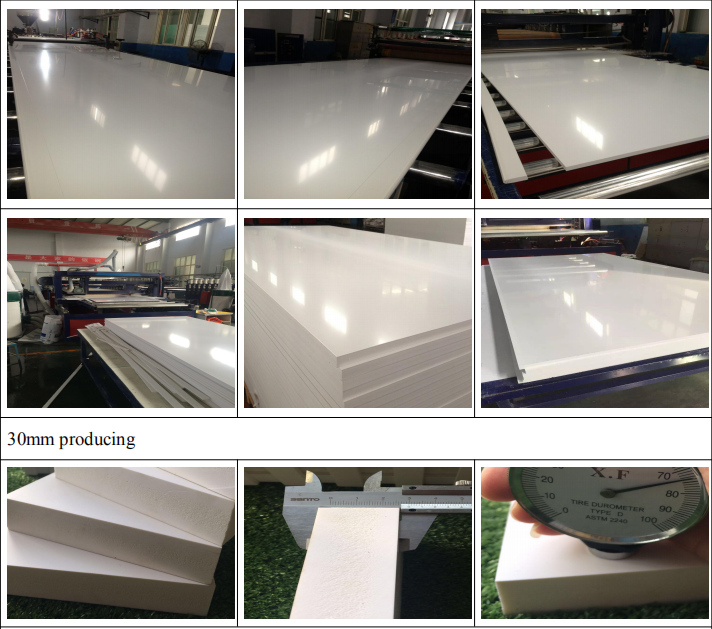

High Density Pvc Foam Sheet

Premium pvc foam sheet made through foaming and pressing into shape. The main material is PVC resin, other materials like Calcium Powder and Additives,etc.

Because the foaming technology, so the min and max density has high production cost than normal density and more difficult to produce.

Min denstiy 0.35g/cm3, Max density 0.9g/cm3, normal density 0.5g/cm3, 0.6g/cm3, etc

High density pvc foam sheet surface hardness can be 90D.

Sheet 1: Dimension, Density And Color

Size: Width x Length | 915*1830mm | 915*2440mm | 1220*1830mm | 1220*2440mm |

1560*3050mm | 2050*3050mm | 610*610mm | Customization | |

Density: =weight/volume g/cm3=kg/m3 | 0.45g/cm3= 450kg/m3 | 0.50g/cm3= 500kg/m3 | 0.55g/cm3= 550kg/m3 | 0.60g/cm3= 600kg/m3 |

0.65g/cm3= 650kg/m3 | 0.40g/cm3= 400kg/m3 | 0.37g/cm3= 370kg/m3 | Customization | |

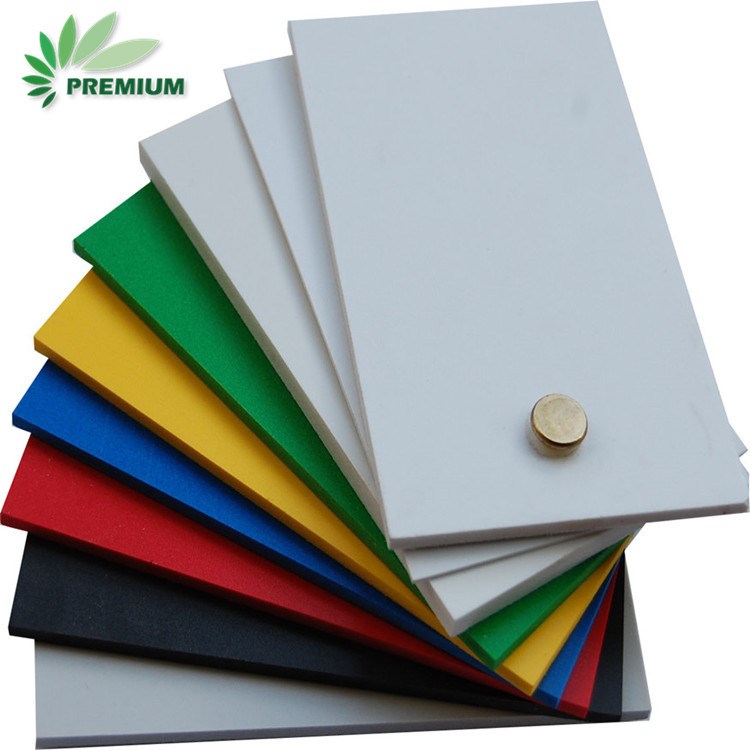

Color | white | Grey=gray | black | wood |

red | green | yellow | Customization |

Sheet 2: Technical Parameter

Bulk Density | 0.35-0.9 g/cm3 | Shore Hardness | 40-80D |

Water Absorption | <1% | Dimensional Stability | ±2% |

Tensile Strength | 12-20 Mpa | Flexural Strength | 12-18 Mpa |

Impact Strength | 8-15 KJ/m2 | Screw Holding Strength | >800 N |

Elongation At Break | 15-20% | Flexural Modulus | 800-900 Mpa |

Vicat Softening Temperature | 73-76 ℃ | Heating Dimensional Variation Ratio | +2% |

Hydroscopicity | ≤1% | Fire Resistance | self extinguishing within 5 second |

Sheet 3: Packing:

Waterproof plastic bag | Carton box | Brown paper | Pallets |

PVC Foam Board Features:

(1) New particularly lightweight materials, green & environmental protection, no pollution

(2) Uniform surface,more bright white, more suit for digital printing.

(3) Fire retarding and self extinguishing within 5 second.

(4) Waterproof, moistureproof and mildew prevent.

(5) Sound insulation, heat preservation, electric insulation.

(6) Easy to process, cut, saw, paint, nail, drill, gluing, route CNC, stamping, same with wood.

(7) Firm and durable, long service life.

(8) Saving energy, recycle and reuse.

(9) Widest rang of dimension and thickness, widely used for printing,spraying,sign and display,engraving,decorating,film laminating ,embossing,furniture,building, etc

(10) No contain lead, protect environment.

PVC Foam Board Processing Performance:

(1) It can be processed by drilling, sawing, nailing, planning and bonding

(2) It can be in Hot-Forming, Hot-Bending and Hot-Folding

(3) It can be welded and bonded with other PVC materials

(4) The surface is very smooth and suitable for printing

PVC Foam Board Application:

(1) Advertising: exhibition display, digital printing, silk screen printing, computer lettering,sign board, light box,etc.

(2) Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf, room separating

(3) Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layerand other industry.